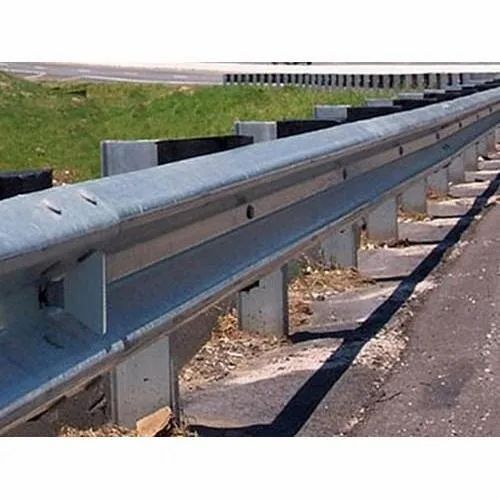

Metal Beam Crash Barrier

Product Details:

- Material MS

- Usage Safety

- Alarm No

- Color Silver

- Click to View more

Metal Beam Crash Barrier Price And Quantity

- 2200 INR/Meter

- 100 Meter

- 1980.00 - 2200.00 INR/Meter

Metal Beam Crash Barrier Product Specifications

- Safety

- Silver

- MS

- No

Metal Beam Crash Barrier Trade Information

- 3000000 Meter Per Day

- 1 Week

- All India

Product Description

A metal beam crash barrier's main function is to deflect and deflect the impact energy of a vehicle in the case of a collision. The beams and posts of the barrier are made to bend and absorb kinetic energy when a vehicle strikes it, lessening the force of the impact on the car and its occupants.

Metal beam crash barriers are frequently built of strong, long-lasting materials like steel or galvanised steel. Various transport and safety authorities regulate the planning and building of these barriers to make sure they adhere to strict performance standards.

Metal beam crash barriers come in a variety of designs, such as the following:

1. The most popular kind of metal beam barrier is the W-Beam Barrier. It is made up of a number of vertical supports and W-shaped steel beams. The horizontally mounted beams are made to bend and absorb impact energy.

2. Thrie-Beam Barrier: The thrie-beam barrier has a modified shape with three ridges, much like the W-beam barrier. It provides improved protection and is frequently utilised in areas with high traffic volumes or high crash severity.

3. High-tension steel cables attached to posts are used in cable barriers rather than solid metal beams. On contact, they are made to flex and absorb energy while also preventing cars from veering into oncoming traffic.

4. Concrete Barrier with Metal Beam Insert: A concrete barrier occasionally has a metal beam insert, which strengthens the structure and improves its capacity to withstand impacts.

Roadside, median, and bridge metal beam crash barriers are deliberately placed, giving priority to regions with increased risks, such as abrupt curves, steep slopes, and locations close to dangers. By lowering the severity of accidents and decreasing the likelihood that cars may leave the road or into opposing lanes of traffic, they significantly contribute to improving road safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+